Harvard Corporation Filtration | Servo Valve Failure

Get a Free Consultation and

Download Our Free Whitepaper

"Servo Valves & Hydraulic Failures"

Extend the Life of Your Oil

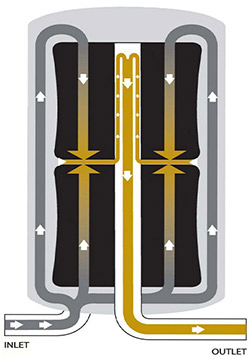

Lubricants with contaminates and moisture wear on expensive and sensitive parts. Our patented filtration systems and filters remove these down to a single micron – literally purifying your oil so it is cleaner than new - reducing costly oil changes, maintenance, and downtime.

Case Study

Harvard started working with a Midwestern engine manufacturer who was experiencing high levels of particle contamination in the hydraulic oil of their high precision grinding machines.

At the time, the current high pressure filters (costing $420.00 each) needed to be changed every 7-10 days, while doing little to nothing to keep the ISO cleanliness code of the grinding machine at the manufacturer's requirement of 17/15/12. The company tried many different filters with no success.

Options:

The company had a couple of options:

- Take the grinding machine offline and flush the hydraulic system, adding downtime and service cost, or

- Try Harvard's depth media kidney loop system.

The company decided to try the Harvard constant contamination control solution for 60-days. During the trial, Harvard's system did not require any downtime and while the Harvard system was on duty, the high-pressure filters that they previously changed every 7-10 days didn't need to be changed either.

Since the Harvard solution demonstrated to the engine manufacturer that our system not only kept the oil "servo clean", but also saved them countless hours of downtime, they added the Harvard system to all of their other companion machines adding a total of 5 more units to their grinding machine operations.

Our new customer had a return on their investment (ROI) in less than 6-months of using their new Harvard products.

After almost four years of use among all 5 of their grinding machines, our customer is able to keep their hydraulic oil under the manufacture's requirement. They also get 6-10 times longer life out of each full flow filter.

To learn more about how Harvard filtration systems can help keep your oil cleaner and reduce your machine downtime, complete the form above for a one-on-one consultation with a Harvard expert and download our whitepaper on how one company reduced downtime and increased the life of their grinding machine oil.

To learn more about how Harvard filtration systems can help keep your oil cleaner and reduce your machine downtime, complete the form above for a one-on-one consultation with a Harvard expert.

Testimonials

- “

The Harvard filtration system has significantly reduced down time at our plant, it has also increased bearing life by 5-6 times, just by doing a 20-minute oil service interval on each pump 3-4 times a year. - “

My oil is cleaner, it has eliminated sticking valves, which in turn has also eliminated hose bursting, it increased my oil service life by 5-8 times, and it has added significant operational uptime causing more production output. - “

On my hydraulic oil in my Cat loader, I went from an ISO 18/13/11 to an ISO 14/8/>7. That is a huge cleanliness standard jump, and has saved me tons on my equipment costs.

Trusted, Experienced, Professionals